Design Guidelines

Profiling

Laser machining flats, slots and complex shapes.

Our general tolerances for the most cost-effective manufacture of laser profiling:

-

Length and width between profiled edges: +/- 0.05 mm

-

Profiled edge to hole centre: +/- 0.05 mm

-

Narrowest cut (profiled) slot: 0.1 mm

-

Corner radius: >/= substrate thickness (specify internal corner radii to minimise the risk of micro-cracking)

Scribing

Accurate and reliable laser scribing to customer specifications.

Laser-scribed substrates are normally supplied without tooling or computer part program costs.

Our general tolerances for the most cost-effective manufacture of laser-scribed substrates:

-

Depth of scribing between 30 - 50% of the material thickness (or by arrangement)

-

Laser pulse spacing normally +0.15/-0.02 mm from centreline to centreline (or by arrangement)

-

Edge to design. The border edge to be snapped off should be at least 5 times the material thickness

-

Distance between scribed edges: +0.15/-0.05mm

-

Distance from laser-scribed/laser-profiled edge to first scribe line: +0.15/-0.05 mm

-

Distance from scribe line to scribe line: +/- 0.05 mm

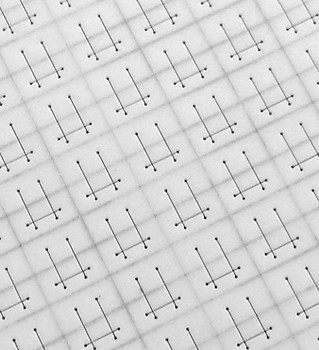

Drilling

Accurate hole drilling (random positioning or step and repeat patterns).

Minimum hole diameters:

Pulsing: 0.1 mm

Drilling: 0.15 mm

Our general tolerances for laser drilling:

-

Hole diameter: +/- 0.05 mm

-

Hole tapers: ~ 5% of the substrate thickness

-

Hole centre to hole centre: +/- 0.05 mm

-

Wall thickness between adjacent holes: >/= the substrate thickness

-

Wall thickness between hole edge and another edge: >/= the substrate thickness

-

Scribed edge to hole centre: +0.15/-0.05 mm

-

Profiled edge to hole centre: +/- 0.05 mm

-

Centre of scribed line to hole centre: +/- 0.05 mm

Additional Design Guidelines

Camera Alignment

High quality circuits can be precision laser cut after printing or sputtering.

Protective Coating

A protective coating can be applied before laser processing to minimise glassification of molten ceramic.

Reference Marking and Datum Corners

Pencil marks, lasered holes, scribed crosses or other markings can be applied to your specification for positioning purposes.

Tolerances

All dimensions are non-cumulative.